Maintenance

Rotor

The rotor surface must be inspected regularly. Rotor fouling is affected by air quality, filter type, filter condition and air leakage etc. Base inspection frequency on the above factors. Ostberg recommends that inspections be carried out at least once per year.

Check that the periphery plates overlap correctly; see illustration.

Ostberg recommends that inspections be carried out at least once per year.

- Rotor

The rotor surface must be inspected regularly. Rotor fouling is affected by air quality, filter type, filter condition and air leakage etc. Base inspection frequency on the above factors. Ostberg recommends that inspections be carried out at least once per year.

Project Planning advice

Recommended installation

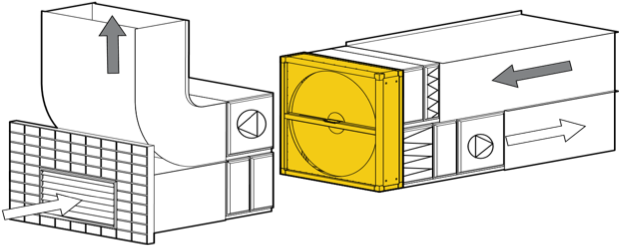

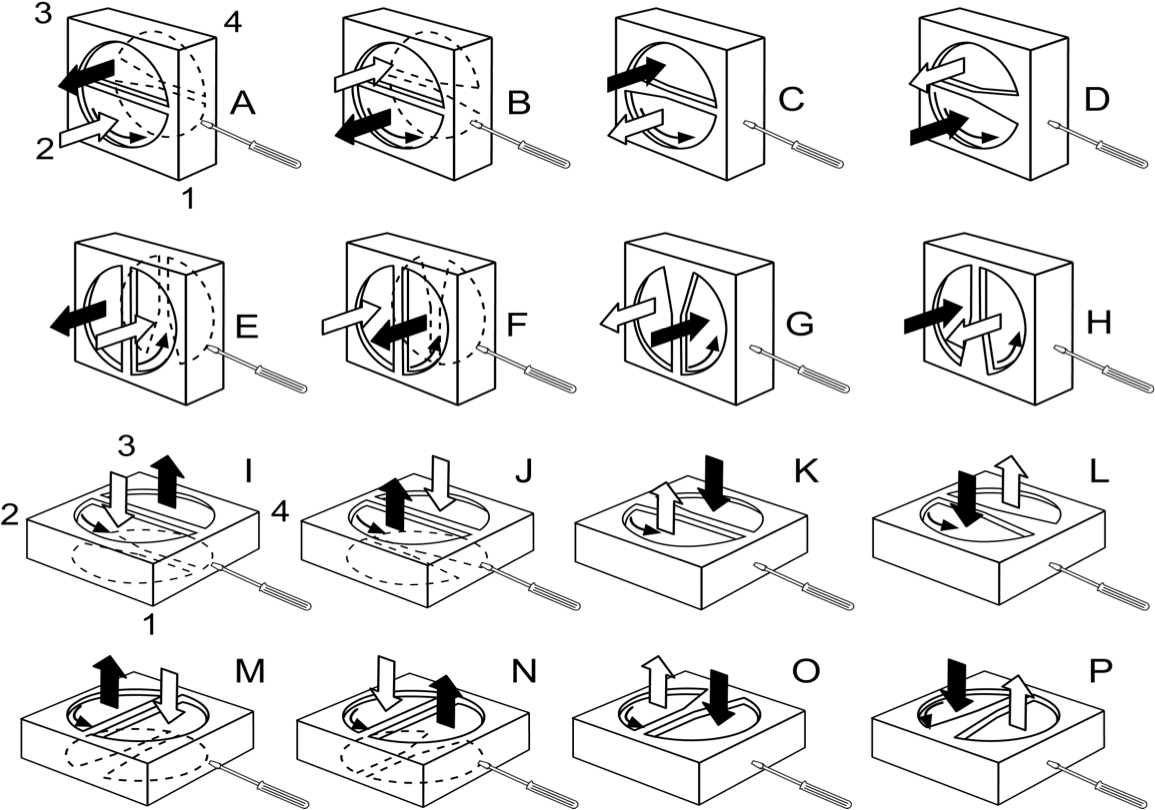

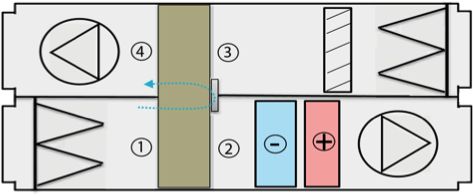

The best flow conditions are achieved when supply and exhaust air fans are installed on the suction side of the regenerative heat recovery unit. A reasonable pressure difference between the supply air and exhaust air ducts p2-3 is obtained in almost all installations. It is possible to install a trim damper in the exhaust air to regulate pressure difference p2-3.

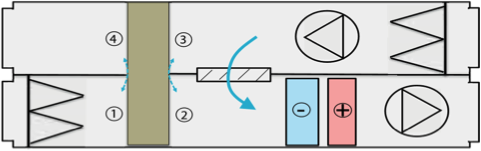

Alternatively, the outside airflow fan can be located in the direction of flow upstream of the rotor. This variation is often found in hospital installations where the entire supply air section is run at overpressure. The risk of supply air contamination is thus eliminated. Furthermore, installations with pusher outside air fans are of interest when maximum cooling recovery is preferred, as the heat generated by the outside air fan is largely transferred to outlet air via the rotor.

Constant pressure and recirculating air

Blow through exhaust air fans and draw through outside air fans are typical in installations with a recirculating air function, or in installations where constant duct pressure is necessary. Furthermore, exhaust air fan heat generation contributes to heat recovery.

The system leads to a negative pressure differential between p2-3 and because a purge sector is unable to function correctly, it should not be installed. Therefore blow through exhaust air fans should only be used in systems where recirculating air is allowed.

Inspection

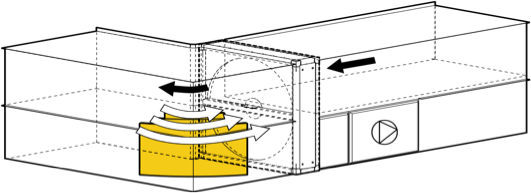

It is important when installing rotors to consider service, maintenance and cleaning. Hatches are necessary on the inspection side to allow access to control equipment, motors, drive belts and brushsealings.

Airflow disturbance

Rotor performance calculations are based on undisturbed airflows in and out. Because very uneven airflow speed profiles have a negative effect on rotor performance, component location should be carefully planned in a ventilation installation.

If the rotor is e.g. installed in direct connection to a right-angle duct, guides should be installed in the duct so that air speed is evened out as far as possible. When installing a radial fan on the pressure side of the rotor, and air diffuser should be fitted.

Distance to components

Generally speaking, air handling components should not be placed too close to the rotor in order to prevent in- and outflow disturbances to the rotor.

Air containing particulates

Experience shows that the rotor can be run with a moderate amount of particulates in the air. Due to the laminar airflow inside the rotormatrix a self-cleaning effect is achieved when the rotor switches airflow directions between outside and exhaust air. If particulates does remain on the outer surface of the rotor these can be vacuum cleaned or washed away. It is always recommended to install an air filter in the direction of airflow upstream of the rotor in order to protect the rotor from contamination. It is advisable to install an exhaust air oil filter in installations with kitchen exhaust air.

Installation and motor Position

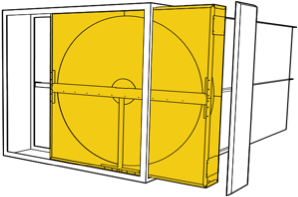

Rotary heat exchangers can be installed in units in several different ways. Ostberg has two different casing types independent of rotor size. The choice of slide-in or modular unit depends mainly on the air handling unit’s design and desired technical performance.

Ostberg has different types of slide-in casing for units for incorporation into air handling units, depending on the size requested.

Modular units are available when the customer wants to connect the rotor directly to the unit or ducting. This design allows a rotor larger than the unit in order to maximize technical performance. The way in which the rotor assembly is connected to unit components is determined by the customer. Connection parts are not supplied by Ostberg.

Rotors for both versions can also be supplied for horizontal installations <Ø3200mm. Correct function is ensured by following the installation instructions available on our website.

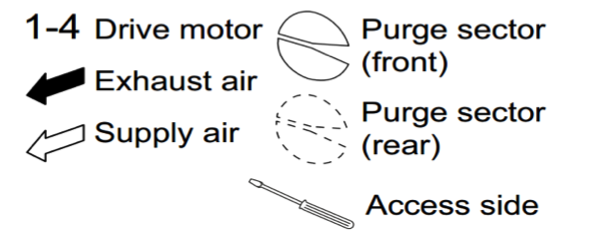

When dimensioning heat exchangers in Ostberg Calculation, units are shown in the standard version with a purge sector. In order to locate the purge sector correctly, it is necessary to know unit set-up in regard to exhaust air, supply air and the inspection side.