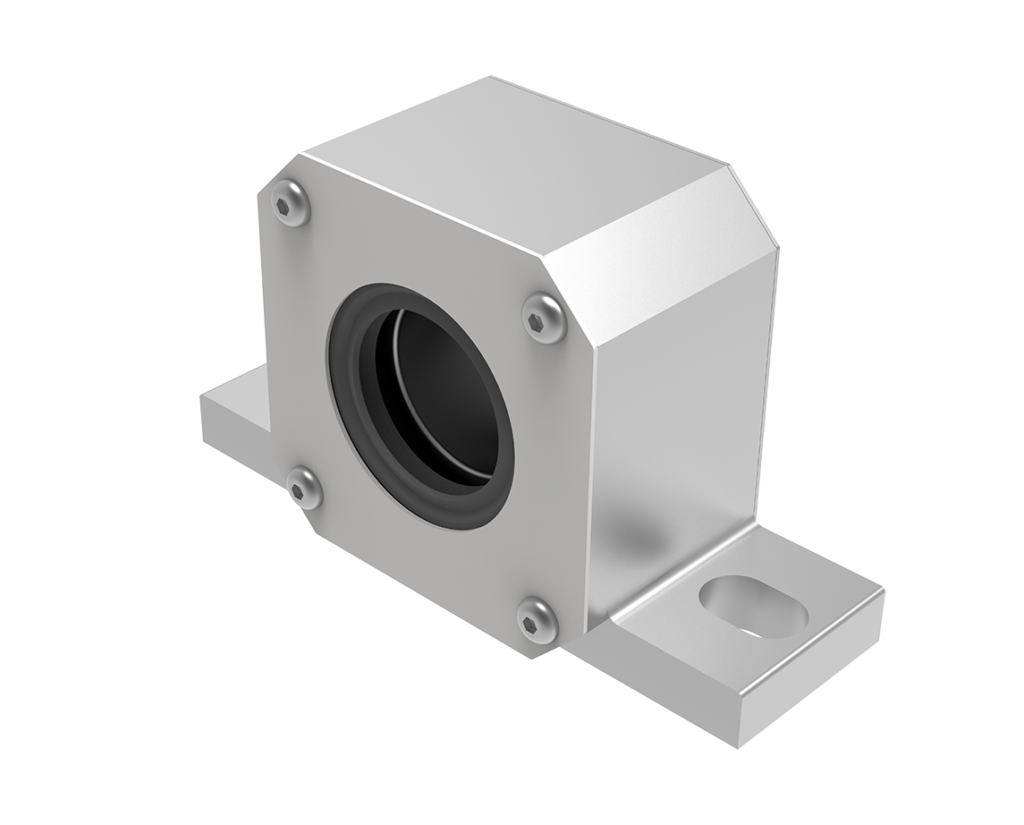

Ostberg Heavy Duty Bearing Holder eXtreme

Bearing holder eXtreme is designed to protect the bearing from the surrounding environment, the protection of bearing is taken from the philosophy from car- industry. A breakdown of a bearing in a car is not only costly it’s also a life threatening and can lead to severe and costly damages, and in worse case accidents.

Breakdown in a ventilation equipment is not as severe as a car accident, but it will create disturbance of the guest’s climate comfort, it will create emergency work, it will create additional cost and it might also result in damages of the wheel resulting in even bigger material cost and longtime disturbance of the guest’s comfort.

Ostberg’s goal is to offer a solution, not only a standard bearing holder, but that can also be found as a standard part on the market today. We believe in tailor the product(s) for its purpose and by that provide a higher value to the customer, an experience that exceeds the customer expectations.

The most common reasons for break-down of bearing is corrosion, the marine environment puts extra stress on the bearing and normally shorten the lifetime of the bearing significant. The best way to prevent a bearing failure is to protect the bearing from the source that creates the risk. Therefore, we decided to design a bearing holder that creates a sealed capsule around the bearing.

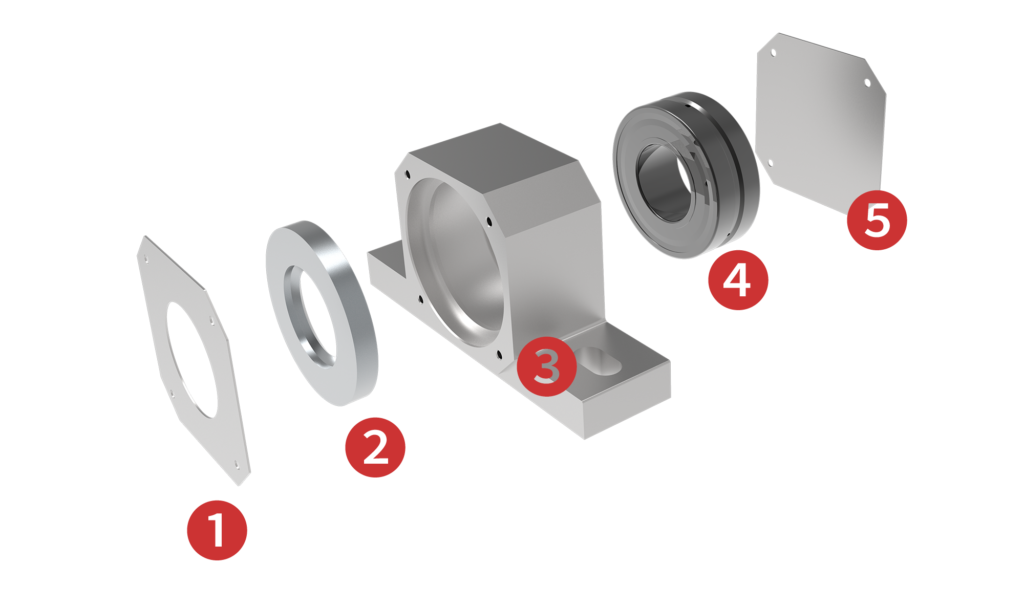

❶ The “front” end- cover secure that the important Radial shaft seal always is in place and provide an extensive protection of the Radial shaft sealing.

❷ The Radial shaft seal efficiently protects the bearing from being exposed for turbulent, humid, and polluted air. The additional Radial shaft seal is the “gatekeeper” to secure that the bearing is completely sealed off from outside conditions.

The Radial Shaft seal provides a fully closed area around the bearing = optimal environment for a bearing in a very complex environment with, turbulent air contaminated by humidity and salt.

❸ Solid CNC- manufactured body. The whole bearing body is Zinc-Nickel plating widely used in automotive industry for corrosion protection. Connection holes to the support is 11.5 x 17.5mm for easy positioning.

❹ Spherical roller bearing, SKF BS2-2206-2RS/VT 143 or SKF BS2-2208-2RS/VT 143 (depending on the rotor’s ø). The bearing is lifetime lubricated and have a rubber sealing on both sides of the bearing.

❺ SST 304 “back” end- cover. This cover seal of the bearing from the back side, this efficiently prevents air and pollution to reach the bearing.